Introduction: Why “Automation” Isn’t a One-Size-Fits-All Term

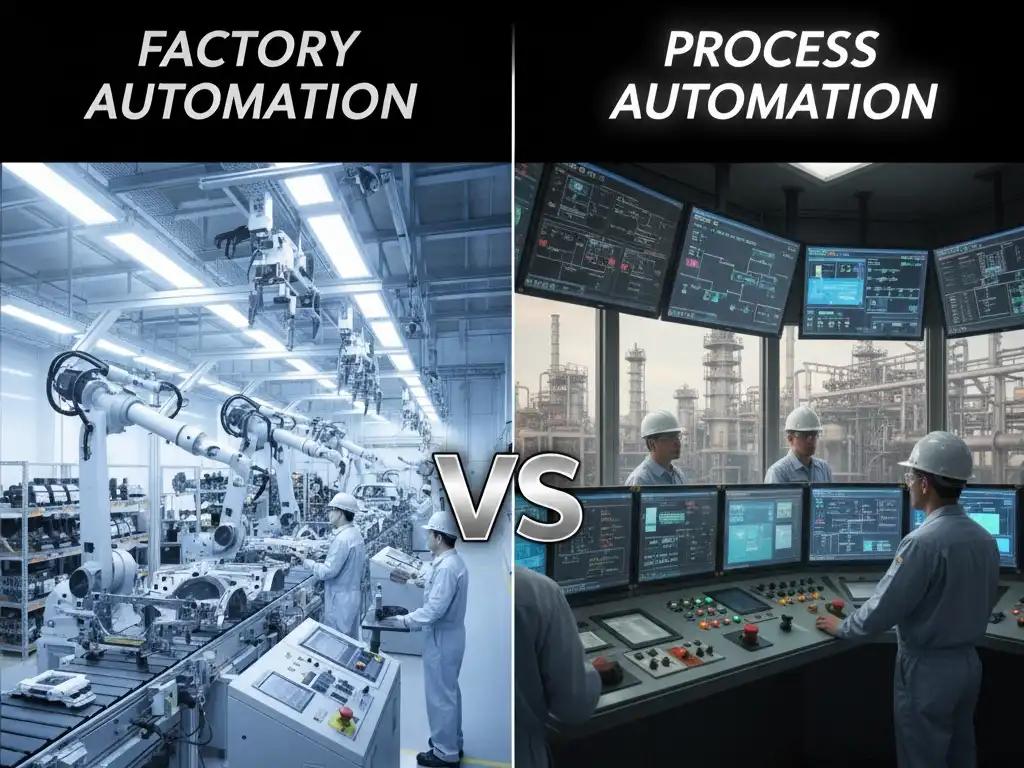

Within contemporary industries, automation and more broadly, industrial automation is followed as a pathway to efficiency and precision. While this is correct, it is a critical strategic error to treat “automation” as a one single, monolithic concept. It is a one-size-fits-all label for a wide range of automation solutions without consideration to Factory Automation (FA) andProcess Automation (PA) being two different disciplines, just two of the main types of automation.

These two pillars of modern production not only differ in their application, they also stem from different specific needs, different foundational control systems and principles, and different systems of measurement. The difference is not merely semantic; it is fiduciary. Incorrectly choosing an automation philosophy means capital misallocation, system inefficiencies, a technology-goal mismatch, and a lack of goal cohesion.

We will investigate these two concepts and their core components, identifying a definitional system to describe each. By the end of this analysis, you will be able to understand the pillars of production, identifying not only where they differ and overlap, but also the importance of that difference in your systems.

What is Factory Automation (FA)? The World of Discrete Manufacturing

At its core, factory automation is the world of the thing. This is the domain of discrete manufacturing, the primary focus of factory automation systems. Its entire focus is the production of quantifiable, separate, and tangible items—units you can count, hold, and put in a box. Consider a car door, the logic board of a smartphone, a medical syringe, or a running shoe. Each of these units is a discrete ‘piece’ and travels to the next stage in this manufacturing process in a sequence of operations to be transformed.

Factory Automation, which excels at high-volumerepetitive tasks with minimal human intervention, speed, repeatability, and precision, takes center stage. This drive for production efficiency leads to the key questions:

- How many units can we produce in an hour (throughput)?

- Is every unit functionally identical to the last (consistency)?

- Is the robotic arm placing that microchip with a tolerance of 10 microns (precision)?

An FA system consists of a series of operations carried out by machinery in an environment defined by high-speed parameters to perform specific tasks. Each component is functionally identical, and the system is ‘motion’ and ‘position’ defined, with assembly lines or a broader production line comprising the rest. A component is gripped, moved, positioned, welded, screwed, placed, or inspected, and the cycle of these specific functions repeats, thousands of times a day. The objective value lies in high-speed identical replication.

What is Process Automation (PA)? The World of Continuous Manufacturing

If FA is the world of the “thing,” Process Automation is the domain of the stuff.

This is the world of process manufacturing (also known as continuous manufacturing) or, in some cases, batch manufacturing. Its focus is not on countable units, but on an amorphous “material” that is mixed, heated, cooled, pressurized, or chemically altered. The output is not counted; it is measured by volume, by weight, by flow rate. Think of gasoline from chemical processing, paint, pharmaceuticalpowders, municipal water, or energy production.

The primary goals of Process Automation are stability, safety, and consistent qualityto ensure operational efficiency. The central questions are:

- Is the temperature in the reactor vessel exactly 400°C (stability)?

- Are the flow rate and pressure in this pipe within safe operational limits (safety)?

- Is the chemical composition of this batch identical to the last (consistency)?

The PA environment is a highly controlled system of transformations, where inputs are converted into a bulk output. The entire system is often treated as a single, large, interconnected process. The primary concern is maintaining a perfect state of equilibrium, often with minimal human involvement due to the scale and potential hazards, which also reduces the risk of workplace accidents. A 1% deviation in temperature or pressure could be wasteful at best and catastrophic at worst. The value is in the flawless, stable transformation of raw materialsinto a finished, bulk product.

The Core Differences: A Head-to-Head Comparison

For a comprehensive understanding of the divide, we should evaluate the philosophies juxtaposed on a single plane. The differences in philosophies from the production floor to the nerve center are foundational.

Production Output: Discrete Pieces vs. Continuous Flow

In factory automation, this is the most intuitive difference. In factory automation, the output is a finished, discrete product. In terminal production, you end your production line with a SKU (Stock Keeping Unit). You can apply a serial number to it. A car, a laptop, a box of cereal. The process is defined by sequential steps acting on a part.

In process automation, the output is a product, but it is undifferentiated. You end your production line with a recipe or a formula. The output goes into a tank, a silo, or a pipeline. You measure it in gallons, or cubic meters. The process is defined by continuous conditions acting on a flow.

The closest PA gets to discrete units is “batch” production (common in pharmaceuticals or specialty chemicals) where a specific amount of material is created at once. Even here, the control philosophy is managing the process (temperature, mixing time) of the batch, not the assembly of its parts.

Control Systems: PLC & Robotics vs. DCS & SCADA

This is where the differences in automation technologies become a bit more technical in nature. The “brains” of the operations in these systems and the business processes they support are built for fundamentally different tasks.

In the case of Factory Automation, it is the PLCs and Robotics that take over.

- ForPLC (Programmable Logic Controllers): “A PLC is the backbone of high-speed, sequential logic. These industrial controllers are ruggedized industrial computers designed to make ‘yes/no’ or ‘if-then’ decisions in milliseconds. Its logic is sequential: ‘Is the part in place? Yes. Activate pneumatic clamp. Is the clamp secure? Yes. Activate welder. Is the weld complete? Yes. Release clamp.’ This type of functionality is built for the high-speed I/O (Input/Output) demands sensors, switches and actuators requires.’ “

- For Robotics: This involves robotic systems with specialized motion controllers that manage the complex, multi-axis movements of the robotic arm for tasks that involve picking, placing, welding or painting.

In the case of Process Automation, it is a DCS (DistributedControl System) that automates the processes.

- DCS: A Distributed Control System serves as a process-wide control system. It may not be built for millisecond responsiveness, but for massive, system-wide reliability. It handles analog massive simultaneous data inputs from temperature, pressure, and flow transmitters, for thousands of feedback loops. The control system, often part of more advanced control systems, uses complex algorithms to maintain equilibrium by executing complex, cascading control loops illustrative of “on/off” control; for example, “open this valve 32.5% to hold the temperature at 90.1°C.” It is designed for redundancy and system-wide visibility, ensuring the entire plant operates as a single, stable entity.

- SCADA(Supervisory Control and Data Acquisition): Often used for data collection and visualization, SCADA is frequently employed as the overarching HMI (Human-Machine Interface) that permits controllers, often via central dashboards or mobile tablets, to observe and oversee the entire process, which is frequently distributed across a large area.

Monitored Variables: Position & Speed vs. Temperature & Pressure

The distinction can be explained by how the different systems are controlled.

Factory Automationfocuses on movement, and on discrete variables (often represented by digital measurements).

- Position (Is the part here?), presence (Is the box full?), and count (How many units passed?) are the variables.

- Control can be speed (How fast is the conveyor?), sequence (What is the next step?), and binary (Is the motor on or off?).

- The world is defined by events.

Process Automationfocuses on the physical states, and on analog variables.

- The variables are temperature (How hot is the reactor?), pressure (What is the PSI in the pipe?), flow (How many gallons per minute?), level (How full is the tank?), and pH (What is the acidity?).

- Control can be modulating (Open the valve 20%), proportional (Gently increase heat), and maintaining (Hold this pressure steady).

- The world is defined by conditions.

Typical Industries: Automotive & Assembly vs. Oil & Gas

Where you find these systems in the wild makes the distinction crystal clear.

| Feature | Factory Automation (FA) | Process Automation (PA) |

| Manufacturing Type | Discrete Manufacturing | Process / Continuous Manufacturing |

| Core Output | Things (Countable Units) | Stuff (Measured Volume/Weight) |

| Primary Goal | Speed, Throughput, Precision | Stability, Safety, Consistency |

| Core Control System | PLC (Programmable Logic Controller) | DCS (Distributed Control System) |

| Key Components | Robotics, Servos, Pneumatics, Sensors | Control Valves, Transmitters, Pumps |

| Key Variables | Position, Speed, Count, On/Off | Temperature, Pressure, Flow, Level |

| Typical Industries | Automotive Assembly, Electronics (and product design), Consumer Goods, Packaging | Oil & Gas, Chemicals, Water Treatment, Power Generation |

The “Muscle” Behind the “Brain”: Key Components That Execute Commands

A control system, be it a PLC or a DCS, is a “brain.” It makes decisions and issues commands. But a brain without a body, without “muscle,” is inert. The real work of automation is not in the decision, but in the physical execution of that decision.

This is where components—the actuators, valves, grippers, and sometimes hydraulic systems—come in. They are the tangible interface between the digital command and the physical world. In PA, this “muscle” is often a large, modulating control valve, sitting on a pipe and slowly adjusting its opening by a few percentage points to regulate flow. It is built for high pressure, hazardous environments, and precise analog control.

But in the high-speed, high-cycle world ofFactory Automation, the demands are far more dynamic. The “muscle” here must be fast, reliable, and powerful, ready to execute millions of cycles without fail. This calls for a different kind of workhorse.

The Workhorse of FA: Why Pneumatic Components are Essential

At HEBAI, we understand that Factory Automation (FA) relies on one core truth — every second counts. Whether it’s clamping, positioning, sorting, or transferring, modern production demands millions of precise, repeatable actions every day. Pneumatic components are the workhorses that make this rhythm possible. With response times faster than most electromechanical systems and the ability to sustain millions of cycles (3–10 million typical lifespan), our cylinders and valves ensure each motion is both accurate and enduring — even under harsh, high-frequency conditions.

Our pneumatic cylinders and valve systems are built to sustain the pace of modern automation. Designed with IP65–IP68 protection, they deliver smooth, efficient movement with minimal vibration and noise — perfect for applications in electronics, automotive, food, and packaging. With precise machining and premium seals, they reduce downtime, extend equipment life, and ensure that your automation cells run continuously with confidence.

And because efficiency is more than just speed, we’ve engineered our FRL units (Filter-Regulator-Lubricator) to deliver clean, stable, and energy-efficient air power. With 0.1–1.0 MPa regulation, 25–40 μm filtration, and 500–4000 L/min flow capacity, our FRL systems protect every actuator and valve downstream — eliminating pressure drops, oil contamination, and inconsistent motion. For FA integrators, that means a more reliable line, fewer maintenance interruptions, and optimized cycle times — exactly what every smart factory demands.

When the Lines Blur: Understanding Modern Hybrid Systems

Although different, FA and PA are often used together in modern facilities, which are “hybrid” systems. Depending on the level of automation, you might see elements of fixed, programmable automation, or flexible automation all in one plant. In reality, the systems used are facility automation and process automation.

Food and beverage, especially yogurt, and pharmaceuticals are common examples.

- In the Front-End (PA), yogurt facilities automate the “yogurt” pre pasteurization processes (blend milk, yoguard cultures, and fruit), and store the mix in huge pasteurization and temperature controlled vaults. This is Process Automation, most probably running on pre-set DCS. Control and automation temperature, mixing durations, and flow rates are critical variables.

- Back-End (FA), the packaging line, is Factory Automation. The yogurt “stuff” is fed to a high-speed filler. The empty cups “things” are indexed (PLC controlled), filled, sealed, and capped and boxed (pneumatics, actuators) under the supervision of complex robotics systems.

An engineer in the facility needs knowledge of both systems. Integration is speaking process automation (DCS, stability) in one and factory automation (PLC, speed, pneumatics) in the other.

How to Choose: Is Your Operation Discrete or Process?

In order to select your automation route, you must first identify your key challenge. When analyzing your production processes with a new or existing production line, here are the key questions and best practices to answer. This will help you find the rightfactory automation solutions or process automation systems.

- Am I making “things” or “stuff”?

- Things: Distinct, countable items. -> You are in the realm of Factory Automation.

- Stuff: A large quantity of material that is measured. -> You are in the realm of Process Automation.

- Is my primary goal speed and throughput, or stability and safety?

- Speed/Throughput: “Units per hour” is your key metric. -> Factory Automation.

- Stability/Safety: “Maintaining setpoints” is your key metric. -> Process Automation.

- Are my key variables position and sequence, or temperature and flow?

- Position/Sequence: “Is the piece in place?” “Is the switch activated?” -> Factory Automation.

- Temperature/Flow: “What is the pressure?” “What is the level?” -> Process Automation.

These answers will not only provide the right automation philosophy, but will also start defining the control systems (PLC vs. DCS) and, the crucial, decision on the system components (pneumatics vs. control valves), that you will require to succeed.

Conclusion: Automation, Precision, and the Right Partner

We began by asserting that “automation” is not a single concept. We have seen that Factory Automation and Process Automation are, in fact, two distinct disciplines, born from different philosophies and executed with different tools.

Factory Automation is the world of discrete “things,” a high-speed series of operations measured in milliseconds and micrometers, and governed by PLCs. Process Automationis the world of continuous “stuff,” a stable and controlled process measured in degrees and gallons, and governed by DCSs.

Ultimately, an automation strategy, often designed to optimize or replacehuman labour, is only as strong as its weakest link. Poor components can undermine quality control and lead to more downtime. The most brilliant control logic from a PLC is useless if the physical component executing the command is too slow, too weak, or too unreliable.

For those in the world of discrete manufacturing—the world of Factory Automation—success is defined by this translation of logic into instant, powerful, and repeatable motion. It is a world that runs on precision, speed, and reliability, allowing human workers to shift from repetitive tasks to supervisory roles, achieving maximum output with minimal effort. It is a world that runs on air. As experts in the pneumatic components that form the essential “muscle” of FA, we understand this world intimately. We do not just supply parts; we supply the speed, reliability, and power that turns your automation logic into a finished product.