Why Improving Manufacturing Efficiency is No Longer Optional

We can start with an undeniable and obvious fact: the quest to achieve manufacturing efficiency is no longer a strategic benefit. It is a basic need to survive.

In a market characterized by unremitting international competition, unstable supply chains, and slim margins, the manufacturer who manages to survive on old processes and tolerable waste is already losing ground. They just don’t know it yet.

But what is manufacturing efficiency?

It is a notion that is misinterpreted. It is not merely, as many think, a question of speed–of getting the line moving, of straining your people, of working machines until they wear out. That is a desperate scramble to the bottom. Real efficiency is a value equation. It is the ratio of the effectiveness with which you can convert raw materials, labor, and energy into a product that your customer is prepared to pay money on, and at the same time use the least amount of those resources possible. It is the value created for the resources used.

Each minute of useless movement, each dollar of material scraped, each hour a machine is idle awaiting a part, this is the friction that is eating away your profitability. Previously, this friction could have been a reasonable price of doing business. It is a serious weakness today. Your rivals are investing in data. Your customers insist on speedy delivery and flawless quality. Costs that you cannot directly control are squeezing your bottom line.

Your process is the only variable you can control. Efficiency is no longer on a project meeting agenda. It is the new baseline. It is the distinction between dominating the market and abandoning it.

The Core Principles: Eliminating Waste and Identifying Bottlenecks

Your journey to production efficiency starts not with a purchase order, but with a new vision. You have to learn first to “diagnose” your manufacturing operation, to observe the invisible forces of the amount of waste that are sucking out your productivity.

The two main principles on which this diagnostic stage is based are: seeing and eliminating waste (the philosophy of Lean) and identifying and controlling your main constraints (bottlenecks). Waste hides in the daily processes, such as unnecessary movement, waiting, rework, and bottlenecks silently determine your maximum throughput. To know how to identify both of them is to know where you really start to improve, and to know how to aim at the few points that will give you the most.

Adopting Lean Principles (5S, Kaizen, and JIT) to See Waste

Lean manufacturing is essentially a war on waste. Waste, is any activity that consumes resources but does not add value in the eyes of the customer, impacting customer satisfaction.

You have to study its shapes: defects (rework), overproduction (making more than is required), waiting (idle time), transportation (unnecessary movement of parts), excess inventory levels (unnecessary stock), motion (unnecessary movement of people), and over-processing (doing more work than is necessary).

Lean offers a set of tools to systematically assault this waste:

- 5S: It is not housekeeping on steroids. It is a five-step system (Sort, Set in Order, Shine, Standardize, Sustain) that establishes a visual, organized, and self-regulating workspace. When everything has a place and is in place, any deviation, a lost tool, a possible safety risk, an out-of-place part, is instantly noticed.

- Kaizen (Continuous Improvement): This is the cultural driver of Lean. It is the assumption that improvement is not a project that managers undertake once, but a daily, gradual process that is owned by the operators themselves. It gives the individuals who do the work the power to identify and correct minor potential issues before they escalate into major ones.

- Just-in-Time (JIT): This concept questions the “just in case” attitude of huge inventories, promoting better inventory management. JIT is designed to establish a continuous flow with no interruptions whereby the correct parts reach the correct station at the appropriate time when they are required. It reveals issues such as unplanned downtime or product quality problems that are usually covered by large inventories (a kind of waste).

How to Find and Fix Your True Production Bottlenecks

Whereas Lean is used to attack waste at all points, bottleneck analysis is used to attack the single point in your production process that controls the throughput of your entire system.

Any resource whose production capacity matches or falls short of the customer demand on it is referred to as a bottleneck. It is the weakest link in your production chain, and a chain is as strong as its weakest link. The high-speed production line of your multi-million dollar can only make as much as the slowest, most constrained step. This is your bottleneck.

How to find it?

Look for the evidence. The most typical indicator of a bottleneck is a huge, chronic stack of Work-in-Process (WIP) inventory that builds up immediately before a particular station. It is the stage of the process when operators are never idle, and downstream operators can be waiting. Use data: monitor the cycle time, production time, and machine performance of every step.

How to fix it?

After identifying it, you should now focus all your attention on dealing with this constraint.

- Exploit: Make sure that the bottleneck machine or station does not stop. Assign it the finest operators, take its breaks, and do preventive maintenance on it like a maniac. Never let it sit idle.

- Subordinate: The rest of the process should be subordinated to the speed of the bottleneck. A non-bottleneck machine can only run faster, which generates additional WIP and chaos.

- Elevate: When you have exhausted the existing capacity of the bottleneck and still require additional capacity, then and only then do you invest in elevating it—a second machine, an automation upgrade, or a process improvements team.

Building a Foundation: Standardizing Work and optimizing Layout

After diagnosing your main waste and determining your constraints, you need to establish a base of stability. There can be no efficiency in a chaotic and varied environment. This is anchored on standardized work and an optimized physical layout.

- Standardized Work refers to the process of creating, writing and following the “one best way” of doing any particular task. It is not about producing hard and soulless labor. It is concerned with establishing a scientific base. The tools of this work are Standard Operating Procedures (SOPs). They stabilize profits, make all operators do the job with the same quality and safety, and significantly decrease mistakes, defects, and human error. In the absence of standardization, there is no baseline. Improvement is immeasurable since your manufacturing process is a moving target, which varies with each shift and each operator. SOPs are the rails that keep your process on track and not falling back into old, inefficient habits.

- Optimizing Layout deals with the physical reality of your manufacturing facility. Your shop floor is not a container, it is a component of your process. An ineffective layout generates a lot of motion and transportation wastage.

*Is a portion of your facility going miles back and forth before it is finished? Does an operator need to walk 20 feet to get a tool that he/she uses every 10 minutes? This is waste, pure and simple.

- A rational design, like a cellular manufacturing design, arranges equipment in a U-shaped cell to follow the efficient production flow. This reduces the distance that parts and people need to travel, enhances communication, and reduces the physical and temporal footprint of your whole operation. An efficient layout causes the efficient path to be the path of least resistance.

Your Greatest Asset: Empowering and Upskilling Your Workforce

Your systems, your machines, your strategies are all dead. They are tools. Your workforce is the sole source of power, wit, and adjustment in your whole manufacturing operation. Sustainable efficiency cannot be attained through dictates in an office. You have to make it on the shop floor.

The most advanced process is of no use when the operator running it is not involved. The most brilliant Lean strategy will not work when the culture is that of fear.

- The first step is empowerment. This is putting your faith in your people. It is about allowing the operators—the real professionals on their stations—the right and the duty to spot issues and recommend solutions. The most important culture is a culture of psychological safety. Does an operator feel safe to “stop the line” and correct a quality control problem or does he or she feel pressured to send the problem down the line to achieve a quota?

- The second step is upskilling. You need to invest in the skills of your people as you standardize work and bring new processes; this is where employee training is critical.

- Cross-training is an effective instrument. Flexibility is enormous when employees are able to do more than one job. The absence of an employee does not close a vital operation anymore. It also creates a more comprehensive picture of the whole value stream because employees can observe the effect of their work on the next person in the queue.

- Problem-solving training provides your team with the Kaizen mindset. Show them the rudiments of root cause analysis. This makes them not a “machine operator” but a “process owner” and “problem solver.”

Efficiency is not something that you coerce people to do. It is a product that you derive from a motivated, skilled and trusted workforce. Operational excellence is a common objective, and it is an objective that is founded on teamwork, respect, and constant development. By empowering and upskilling your people, you make your organization resilient, innovative, and able to maintain excellence long beyond any individual tool or system.

The Technology Leap: Using Automation to Drive Efficiency

You now have a stable base, an engaged workforce, and a clear picture of your bottlenecks, so you are now ready to boost efficiency. This is where technology, in this case, automation, is your greatest lever. This often connects to the Internet of Things (IoT), where sensors provide the data for these leaps.

Automation is not a silver bullet. Trying to automate a non-standardized, chaotic process is a fatal error—all you will do is automate your own garbage and make bad parts go faster than ever before. However, automation is a multiplier when it is used on a standardized, optimized process. It applies human-defined best practices and implements them with a degree of precision, endurance, and speed that is superhuman. It is a device that can conclusively “elevate” your bottleneck. It is the answer to the repetitive tasks that are too boring, too dirty, or too dangerous for your human workforce, and they can concentrate on more valuable work such as quality control and process improvements.

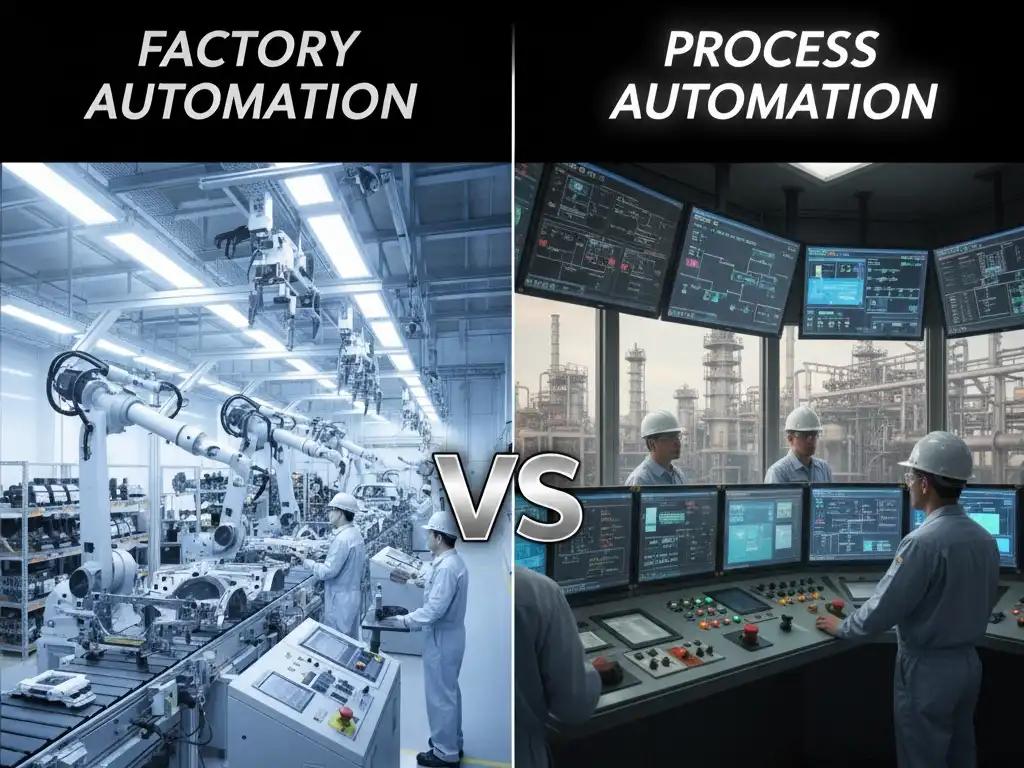

The main obstacle to automation among most manufacturers is a misunderstanding of its shape.

The Workhorse of Smart Automation: The Role of Pneumatic Components

- Maximize Uptime: Reliable Quality, Delivered Fast

- Simplify Sourcing: 3,000+ Models from One Partner

- Built to Last: Lower Your Maintenance & Replacement Costs

- Tailored Solutions to Win Your Market

As Hebai-Omch, established in 1986, we have long demonstrated that smart automation does not have to rely on costly robots or complex electromechanical systems. Across manufacturing, automotive, food processing, and packaging, the most reliable actions—gripping, moving, clamping, positioning—are still powered by pneumatic components. With our full portfolio of FRL air-treatment units, valves, cylinders, fittings, and tubing, all certified under CE / CCC / RoHS, we deliver stable, safe, and efficient pneumatic systems trusted by more than 72,000 customers worldwide.

Pneumatics remains the true workhorse of automation because it offers unmatched stability, durability, and cost efficiency.

- Our AFC/AC FRL series provides clean and consistent air through 25–40 μm filtration, 0.1–1.0 MPa regulation, and 500–4000 L/min flow capacity, ensuring every downstream valve and cylinder operates under optimal conditions.

- Our cylinder family—spanning Ø12–Ø320 mm and strokes from 10–2000 mm—achieves IP65/67/68 protection and 3–10 million cycle durability, enabling smooth, repeatable motion even in harsh or high-frequency environments.

Combined with fast-response directional valves and robust flow-control solutions, our pneumatic architecture supports everything from simple on/off tasks to advanced automation logic.

This is also where pneumatics becomes a strategic enabler for standardization, waste reduction, and speed improvement. Many of the most efficient automation systems worldwide are not the most expensive. They are the most well-designed. Pneumatic components deliver high performance in gripping, moving, sealing, and positioning while remaining affordable, service-friendly, and easy to scale. In other words, automation doesn’t need to be complicated: the right pneumatic system can elevate productivity with minimal cost and minimal downtime.

With more than 3000 items, strong OEM and customization capabilities, same-day shipment under in-stock conditions, and engineering support from drawing refinement to mass production, Hebai-Omch empowers factories to build smarter and more reliable automation systems. Our mission is simple: make high-quality pneumatic technology accessible, consistent, and future-ready, so every factory can automate with confidence.

Sustaining Your Gains: Proactive Maintenance and Data-Driven Decisions

You’ve done the work. You have standardized your processes, involved your people and automated your key bottlenecks. Your production efficiency has been enhanced.

The job is not over. In fact, it has just begun. Efficiency is not a place you get to, but a process that you have to work on. Entropy forces, wear and tear, human error, evolving customer demands, etc. are always trying to drag your process back into chaos.

Your defense is twofold:

- Proactive Maintenance: Unplanned downtime is the most inefficient thing that can happen in any factory. A machine malfunction is a “firefighting” emergency. It is reactive. The line halts, operators wait, and your bottleneck starves. The antidote is Proactive Maintenance (or Preventive Maintenance). A more advanced form is predictive maintenance, which uses historical data and even machine learning to predict failures, but proactive maintenance is the art of maintaining your machine at your own time, before the machine breaks down. It makes maintenance a predictable component of your process instead of a chaotic one.

- Data-Driven Decisions: You cannot make it better without measuring it. You need accurate data and a scoreboard to maintain your gains. This often ties into your Enterprise Resource Planning (ERP) system. Overall Equipment Effectiveness (OEE) and other key performance indicators (KPIs) are the gold standard of manufacturing productivity. OEE decomposes efficiency into three quantifiable elements:

- Availability: (Is the machine running as it should? Or is it undergoing maintenance/changeovers?)

- Performance: (What is its current speed, relative to its theoretical maximum speed? This compares actual output to standard output to gauge performance.)

- Quality: (What is the number of products that are good, first-pass parts, versus scrap or rework?)

A low OEE score is not a failure; it is a diagnostic tool. It is information that puts you right on top of your next biggest problem and makes your continuous improvement process more of a science than a series of guesses.

The Payoff: What Real Manufacturing Efficiency Looks Like

The journey is rigorous. It requires discipline, investment and cultural change. However, the rewards are not only incremental, but transformative. When you manage to establish a culture of efficiency, the “payoff” is experienced in all corners of your business. This is what overall efficiency in the real sense looks like:

| Topic | Description |

| Reduce Operational Costs Drastically | Reduced waste translates to reduced money spent on scrap, rework, and poor inventory management. This means direct cost savings. Increased uptime translates to increased production output (your total output) with the same overhead. |

| Rapid, More Reliable Delivery | A process that flows smoothly, is controlled by bottlenecks, and is guided by smart production schedules implies that your lead times are reduced. You are able to provide your customers with delivery dates and fulfill them. |

| Increased and Improved Product Quality | Uniform processes and employees with authority to correct issues at the source remove the causes of defects, improving your final product quality. |

| A Healthier, More Interested Workforce | A clean, organized (5S) workplace is safer by definition. A cross-trained workforce is more empowered and hence less likely to turnover and ownership culture. |

| A Sustainable Competitive Advantage | This is the prize of prizes. A strategic moat is achieved when you are able to create a better quality product, quicker and at a cheaper price than your competitors. You are not competing on price anymore, you are competing on value. |

This manufacturing excellence is not a one-time project but a continuous effort. True efficiency is the sum of a million little things that have been improved over time- every change that makes your processes smoother, your culture stronger, and your competitive advantage more focused. When your organization internalizes these principles, efficiency ceases to be a project but a way of thinking. Teams start foreseeing issues before they occur, leaders base decisions on facts and not guesses, and operational stability is the basis of innovation and not an obstacle to it.

After all, the real reward is outside the metrics. It is in the assurance that your factory can react to market changes, grow with demand, and provide the same value without compromising quality or humanity. Once efficiency is a part of your identity, not merely behavior, but a part of who you are, you create a resilient, future-ready, and sustainable growth organization. That is what manufacturing efficiency really means: a system that never stops adding value, empowering its people, and putting your business in a position to win not only today, but over the next several years.

Your Next Steps: From Practical Guide to Real-World Action

This guide has laid out a roadmap. But efficiency is built not by reading, but by doing. It is a culture of relentless refinement, not a one-time project. You begin this journey the same way you begin any other: with a single, deliberate step. Do not try to fix everything at once. Go back to the shop floor. Find one bottleneck. Identify one significant source of waste. Start there.

Begin by assessing your most obvious, repetitive tasks. These are your first candidates for improvement, and often the very place where high-quality, reliable pneumatic components can make an immediate, measurable impact. Start small. Win fast. Build momentum. The journey is long, but that first step will already move your manufacturing operation to the next level.

Choose Hebai-Omch, and turn those early, small wins into lasting operational strength through dependable quality and smart pneumatic solutions. With every improvement you make, you’ll build a more efficient, stable, and future-ready manufacturing system.