What Are Factory Automation Components (And Why They’re the Engine of Modern Industry)

Look at any contemporary production line, whether it is a high-speed bottling plant or a high-tech automotive assembly line, and you will be looking at a complex, high-performance automation system in action. This factory automation system consists of factory automation components.

This is the overall name of the whole set of hardware and software that is employed to develop automated industrial processes. These elements are the detecting sensors, the decision-making controllers, and the physical work-performing actuators that work in a strict harmony to carry out a variety of tasks with minimal human intervention. However, this is not merely a discussion on the replacement of manual labor. That is a one-dimensional and old-fashioned perception.

The real significance of these elements is that they are the driving force of modern manufacturing. They are the basic building blocks that enable a business to improve its production processes and do what otherwise cannot be done:

- Radical Efficiency: Automation components do not merely work faster; they work 24/7/365. They are able to do repetitive work with precision and speed that is simply impossible to do manually, which directly translates to increased throughput, lower labor costs, and a more competitive operation.

- Deterministic Quality: Quality is a variable in a manual process. In an automated one, it is a deterministic constant. A vision system will examine 10,000 parts using the same criteria as part of quality control. A controller will perform a welding path with an accuracy of 0.1mm each time. This is the way world-class product quality is constructed and ensured.

- Significant Cost Management: The initial investment is tangible, but the ROI in the long-term is indisputable. Automation reduces the astronomical hidden expenses of human error, rework, and scrap. It maximizes energy use and material consumption, and turns manufacturing processes into a lean, profitable process.

- Increased Worker Safety: This is perhaps the most important, the dull, dirty, and dangerous jobs are replaced by automation elements. They deal with heavy loads, work with dangerous materials, and work in extreme temperatures, eliminating human beings as the objects of danger and promoting their functions to the level of supervisors and technicians.

From the Industrial Revolution’s steam power to the early 20th century’s mass production, the goal has always been optimization. Today’s industrial automation is the next logical step. Understanding this system is no longer an option. To the contemporary engineer, manager, or procurement officer, it is the language of modern manufacturing success.

The ‘Brains’: Control Layer Components

The brain of the automated system is the control layer. This is where decision making and rational implementation takes place. The control layer performs program logic, real-time decisions, and commands all other components. It is the sole source of truth to the whole operation.

In the absence of a strong control layer, you are left with a bunch of unrelated components. It comes with a working, smart system. There are three main components of this layer.

PLCs (Programmable Logic Controllers): The Core Decision-Makers

The PLC is the unquestioned heart of contemporary industrial automation. It is a hardened industrial computer, designed to survive the rough environment of the factory floor-vibration, electrical noise, and temperature changes.

Its task is unique and important: to read a collection of inputs (via sensors), run a user-written logic (e.g., “If Sensor A AND Sensor B are ON, then start Motor 1), and write to a collection of outputs (to control actuators).

A PLC, unlike a desktop PC, is a real-time system, i.e. its I/O (Input/Output) scanning is deterministic and predictable, which is necessary to safely and repeatably control a machine. They are the main instruments of machine control at high speed and logic.

Industrial PCs (IPCs) & SCADA Systems

With more complex automation tasks, it may need more processing power or data-handling capabilities than a conventional PLC. Enter the Industrial PC (IPC). An IPC is a PC that is intended to be used on the factory floor, and may have no moving components (such as fans) and a hardened chassis. It is capable of executing sophisticated programs, handling huge databases, or doing high-level data processing directly on the line.

This is usually accompanied by a SCADA (Supervisory Control and Data Acquisition) system. SCADA is not a hardware device, but a control software system that offers a high-level overview and control. A SCADA system oversees, tracks, and collects raw data and information of various PLCs and other controllers within a plant, providing operators with a clear picture of the whole process.

Human-Machine Interfaces (HMIs): The Operator’s Cockpit

The most advanced control system in the world is useless when an operator is not able to interact with it safely and intuitively. That important bridge is the Human-Machine Interface (HMI).

This is the cockpit of the operator. The screen, panel, or set of buttons that enables a human to monitor the process, adjust settings, and react to alarms is known as the screen. HMIs are no longer just a basic start/stop box with a few buttons, but a high-definition, graphical touchscreen capable of displaying the entire production line in real-time. An effective HMI is not confusing but rather clear and is an essential element of efficiency and safety.

The ‘Senses’: Sensing and Input Layer Components

Without information, a control system cannot operate. The sensing and input layer feeds the control system with information, enabling it to sense and measure the physical world.

These are the input devices of the factory floor. They transform physical phenomena, such as presence, position, pressure, or light, into electrical signals that can be processed by the PLC. This group is enormous, yet two major groups prevail.

Sensors (Proximity, Photoelectric, Pressure, Temperature, etc.)

The simplest input devices are sensors, which respond to the simplest questions in automation: Is something there? Where is it? What is its condition?

Here’s the same information presented in English table format:

| Sensor Type | Description | Typical Applications / Detection Targets |

| Proximity Sensors | Detect the presence of an object without physical contact. Inductive sensors detect metal, while capacitive sensors detect a wide range of materials such as liquids and plastics. | Metal detection, liquid or plastic presence sensing |

| Photoelectric Sensors | Use a beam of light to detect an object. The sensor sends a signal when the beam is interrupted or reflected. | Counting, sorting, position detection, long-distance object sensing |

| Process Sensors | Measure the state of a process. Pressure sensors monitor pneumatic or hydraulic lines; temperature sensors ensure ovens or cooling processes are within spec; level sensors measure the amount of material in a hopper or tank. | Pressure monitoring, temperature control, level measurement |

| Encoders and Position Sensors | Provide accurate feedback on the position, speed, or rotation of a motor or shaft, essential for motion control. | Motor control, robotic positioning, speed measurement |

Vision Systems (Industrial Cameras & Scanners)

A proximity sensor gives a simple binary signal whereas a vision system gives rich visual information. These are sophisticated cameras that scan and process images. A PC-based vision system or an industrial smart camera can do much more than simple sensors can.

Their uses are revolutionary:

– Quality Inspection: A vision system can detect microscopic flaws, ensure that a label is placed in the right spot, or ensure that every part is in place in an assembly- all at hundreds of units per-minute.

– Guidance: They give positional information to a robot, which determines the exact position and orientation of an object to enable the robot to pick it up correctly.

– Data and Identification: Barcode and QR code scanners are a type of vision system, which recognizes all products that pass by and connects it to the data system of the factory.

The ‘Muscles’: Actuation and Motion Layer Components

The system still lacks an important component: the ability to act, with a control layer (brains) and a sensing layer (senses). The system should be capable of moving, gripping, pressing, lifting, or sorting objects physically.

The actuation and motion layer, the muscles of the system, does this. Actuators are devices that transform some type of energy (electrical, pneumatic, or hydraulic) into physical movement. Here, the digital instructions of the PLC are transformed into the real world. One of the most important decisions in the design of automation is the selection of actuator.

Electric Actuation (Servo Motors, Stepper Motors & Drives)

Electric actuation is characterized by accuracy. These systems operate on motors to provide motion, which is usually regulated by complex drives that are fed by the PLC.

| Motor Type | Description | Typical Applications / Advantages |

| Stepper Motors | Move in discrete steps, allowing precise control of position (e.g., rotate 1.8° or advance 10 mm). | Used when exact positioning is required, such as in 3D printers, CNC machines, and robotics. |

| Servo Motors | High-performance, closed-loop systems with encoders providing feedback on position. Enable very high speed, torque, and micron-level precision. | Ideal for applications requiring speed, torque, and accuracy—like industrial automation, robotics, and precision instruments. |

| Variable Frequency Drives (VFDs) | Control the speed of standard AC motors by adjusting the frequency of the electrical supply. | Commonly used for conveyors, pumps, and fans to optimize energy efficiency and motor performance. |

Hydraulic Actuators (For High-Force Applications)

Hydraulics are the solution when the main need is raw, huge power. Hydraulic systems are systems that employ an incompressible fluid (usually oil) that is pressurized by a pump to move cylinders and motors. A small hydraulic cylinder is capable of generating a force that would demand a significantly larger electric motor. They will be found on industrial presses, heavy-lifting equipment and in any place where brute force is the primary goal. Their disadvantage is that they are complex, they need pumps, tanks, and hoses, and leakage may be a serious problem.

Pneumatic Actuators (Cylinders, Valves, Grippers)

Compressed air is a simple, plentiful, and clean source of power used in pneumatic systems. A central compressor supplies air to the whole plant and this air is directed to actuators by means of valves (controlled by the PLC).

- – Pneumatic Cylinders: These are the most widespread. They operate on compressed air to push a piston back and forth producing rapid, high-power linear movement.

- – Pneumatic Grippers: These are employed by numerous robots and pick-and-place systems, where air is used to open and close fingers to hold products.

- – Rotary Actuators: These are air-powered rotational motion.

Pneumatics are characterized by simplicity, high speed, and good cost-to-power ratio.

Industrial Robots (Articulated, SCARA, Cobots)

In a way, industrial robots represent the most sophisticated actuation systems. They consist of a set of several motors (actuators), sensors, and a special controller in a single package.

| Robot Type | Description | Typical Applications / Advantages |

| Articulated Robots | Human-arm type robots with 6 or more motion axes, offering the highest flexibility and range of motion. | Used for complex assembly, welding, painting, and material handling tasks. |

| SCARA Robots | Designed for high speed and precision in a horizontal plane, ideal for pick-and-place and assembly operations. | Commonly used in electronics assembly, packaging, and small parts handling. |

| Collaborative Robots (Cobots) | Modern robots designed to work safely alongside humans, often equipped with sensors to prevent collisions. | Used in shared workspaces for light assembly, machine tending, and quality inspection. |

Why Pneumatics Remain the Unbeatable Workhorse of Automation

With the age of high-tech servo drives and collaborative robots, there is a widespread misunderstanding that pneumatic technology is somehow outdated or rendered irrelevant. This is the last thing that is true.

As a matter of fact, pneumatics continue to be the invincible workhorse of a large and important portion of the automation market. The move to ignore pneumatics and adopt a more modern (and complicated) electric alternative is a decision that can be quite expensive. To be successful, an automation application should be effective, reliable and economical. Pneumatics perform on all three fronts.

This is the reason why, as specialists in the field, we find pneumatics being selected in new designs on a daily basis:

- Sheer Cost-Effectiveness: In simple linear motion, gripping, or pushing applications, Hebai-Omch pneumatic cylinders and valves offer a highly efficient and economical solution compared with electric servo systems. Their value extends well beyond the initial setup: with FRL units rated at 0.1–1.0 MPa and air flow capacity up to 4000 L/min, a single 2–3 kW compressor can reliably power an entire automation line. The simplified configuration—requiring no high-voltage drives or complex cabling—ensures a cleaner layout, easier maintenance, and significant overall savings throughout the system’s service life.

- Unparalleled Reliability and Durability: This is where Hebai-Omch pneumatics truly shine. Our cylinders and valves are mechanically straightforward yet built for strength, featuring precision aluminum or stainless-steel bodies, high-grade seals, and corrosion-resistant coatings. They thrive in environments that would disable electronic dust, high humidity, and up to 60 °C heat. Each sealed cylinder (rated IP65–IP68) easily endures 3 to 10 million cycles, and heavy-duty variants surpass 20 million without maintenance. Whether in food-processing washdowns or gritty factory floors, they embody the definition of “set it and forget it.”

- Unbelievable Power Density:It is hard to match Hebai-Omch pneumatic cylinders in terms of power-to-size ratio. A compact Ø32 mm cylinder operating at 0.6 MPa delivers about 480 N (≈ 49 kgf) of thrust while weighing less than 400 g. This provides up to five times the force-to-weight advantage compared with equivalent electric actuators. Stroke speeds exceeding 300–500 mm/s make them ideal for pick-and-place, packaging, and high-frequency automation. In compact systems, this efficiency translates directly into faster cycles, lighter machinery, and reduced energy demand.

- Intrinsic Safety: Air is the power source behind every Hebai-Omch pneumatic system, producing no sparks and no ignition risk. This makes our cylinders, valves, and FRL assemblies inherently safe and compliant for chemical plants, paint booths, and explosive-dust industries such as grain or flour mills. With stable performance from –5 °C to 60 °C and working pressures up to 1.0 MPa, Omch products maintain full functionality without any electrical hazard. In environments where safety cannot be compromised, pneumatics remain the only rational choice.

This is what we witness as professional manufacturers of pneumatic parts. More than 70 percent of the typical automation ills, such as budget overruns, unforeseen downtime, and line stoppages caused by maintenance, can be linked to a poor selection of actuation. We are not only offering high-quality components, but also designing an application-specific solution that is robust, safe, and, most importantly, long-term economical.

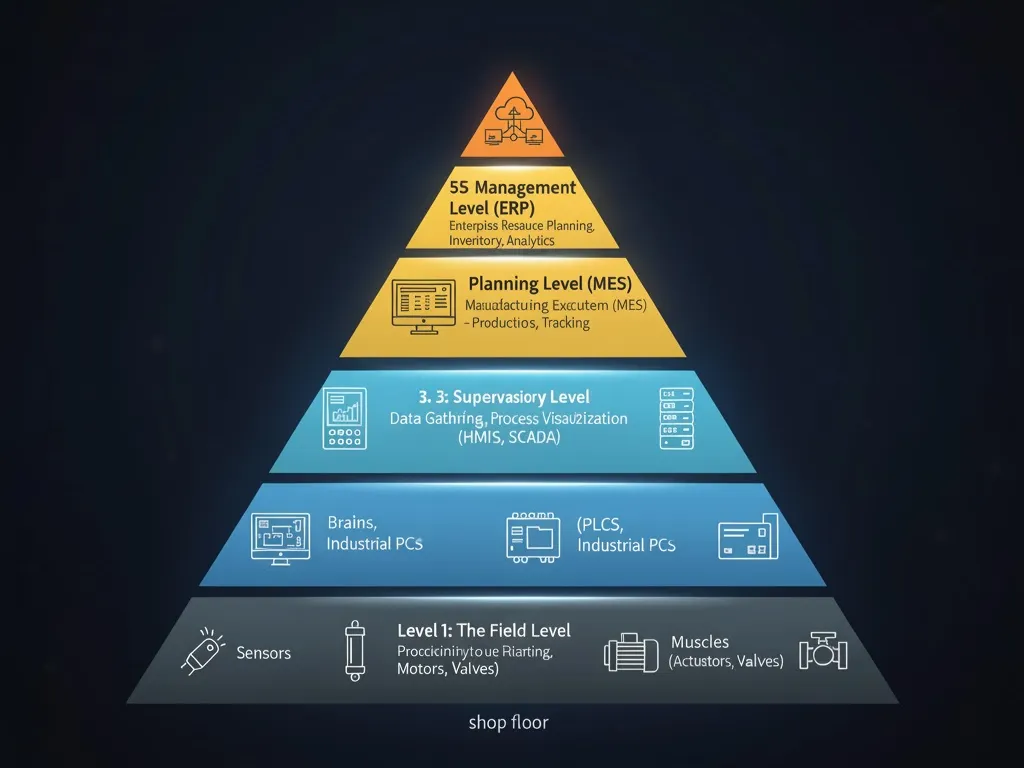

Connecting It All: The Automation Pyramid (How Components Work Together)

We’ve now identified the ‘brains,’ ‘senses,’ and ‘muscles.’ The final piece of the puzzle is understanding how they are all organized. A factory doesn’t just have one PLC and one sensor; it has hundreds.

The classic model for visualizing this is the Automation Pyramid. It organizes the flow of data and controls into distinct levels:

- Level 1: The Field Level: This is the base of the pyramid. It is the “shop floor” where physical work happens. This level contains all our ‘senses’ (sensors) and ‘muscles’ (actuators, pneumatic cylinders, motors, valves).

- Level 2: The Control Level: This is the first ‘brains’ layer. This is where the PLCs and Industrial PCs live. They receive signals up from the Field Level and send commands down to it. This is where all the real-time, high-speed decision-making occurs.

- Level 3: The Supervisory Level: This is where HMIs and SCADA systems reside. This level doesn’t control individual motors in real-time; instead, it supervises the PLCs. It gathers data, displays the process for operators, and allows for high-level commands (e.g., “Start Batch 42,” “Shut down Line 3”).

- Level 4 & 5: The Planning & Management Levels (MES/ERP): This is the top of the pyramid. This is the business software, like the Manufacturing Execution System (MES) and Enterprise Resource Planning (ERP). This level connects the factory floor to the rest of the business—tracking orders, managing inventory, and analyzing long-term performance.

Data flows up the pyramid (from a sensor’s signal to a management KPI), and commands flow down (from a production order to a PLC’s logic).

Key Factors When Selecting Your Factory Automation Components

There is no such thing as the best component. It is just the right component to a particular job. An effective design is a sequence of smart trade-offs. These are the main factors that should guide your decision-making process when choosing the components to use in your system:

–Application Requirements: This is the most important and first filter. What does the component actually have to do?

- Speed: Does it have to move within 0.1 seconds or 2 seconds?

- Load: Is it lifting 1 pound or 1,000 pounds?

- Accuracy: Does it have to be accurate to 1 millimeter (pneumatics) or 0.01 millimeter (servo)? Be realistic in what you really need in terms of precision- over-engineering is costly.

-The Operating Environment: The factory floor is not an office. Where shall this part reside?

- Is it hot, dirty, or dusty? This will strongly lean towards strong, enclosed parts such as pneumatics.

- Is it a food grade or pharmaceutical washdown environment? Components should be all stainless steel and IP69K.

- Hazardous (explosive) environment? This will instantly disqualify the majority of non-certified electronics and necessitate intrinsically-safe components (such as pneumatics).

–System Compatibility & Protocols: There is no component that operates in isolation. What will it say to the rest of your system? You need to make sure that your sensors, drives, and controllers are all in the same language, be it a simple analog signal, hardwired I/O, or an industrial network protocol such as EtherNet/IP, PROFINET, or IO-Link.

–Total Cost of Ownership (TCO): Do not be misled by the sticker price. The actual cost of a component is calculated throughout its lifespan. This includes:

- Acquisition Cost: The original purchase price.

- Installation & Integration Cost: How difficult is it to install and program?

- Energy Cost: What is the amount of power it uses when running?

- Maintenance & Downtime Cost: How much does it cost to maintain, and more importantly, how much does it cost when it fails?

A basic pneumatic system, such as one, can have a near-zero maintenance cost and low acquisition cost, which can often lead to a much lower TCO than a complex electric system in a hostile environment, despite its energy-per-actuation being a little higher.

Your Next Step to a Smarter, More Efficient Factory

We have moved down the ladder of the high-level brains of the PLC, through the senses of the modern sensor, and to the muscles which do physical work. We have observed the relationship between these separate components in a pyramid of data and control, and how the choice of the appropriate one is an important engineering choice.

Automation is not aimed at making things more complicated; it is aimed at creating a strong, stable, and profitable system. The decisions of smart components are the foundation of that system. Whether to use electric precision or pneumatic power, a simple sensor or a complex vision system is not always obvious. This is where experience counts.

When you are in the process of designing a system and considering your actuation choices, call our application engineers today to have a free, no-obligation application evaluation. We can assist you in the analysis of your needs in terms of speed, load, and environment to identify the most robust and cost-effective solution to your particular challenge.