Unlocking Efficiency: An Introduction to Factory Automation

*This video provides a concise overview of factory automation

In the inexorable march of contemporary production, to stand still is to go backwards. The international market is a 24/7 competitive environmentcharacterized by the slenderest of margins, growing customer expectations of quality, and an insatiable drive to do more, quicker, and cheaper. To manufacturers, the wave of change is no longer a far off danger; it is now at the factory doors, washing over them. The only thing that can guarantee survival, not growth, is a strategic imperative: efficiency.

This is where factory automation, and the broader concept of industrial automation, ceases to be a buzzword of the future, but an urgent, current-day reality. The question is no longer whether a facility will automate or not, but when and how. Many businesses seek effective automation solutions to streamline their production processes. But what is this term? What does an actual automated factory look like, beyond the common vision of futuristic robots? What are its moving parts, what are its tangible benefits, and how do you even begin to approach it?

This article will be your guide book. We will de-mystify factory automation, dissecting its main ideas, advantages, and elements. More to the point, we will shed light on the contribution of a strong, frequently-undervalued element of this ecosystem: pneumatic parts. You will learn not only what automation systems are, but why a strong pneumatic system is so frequently the most intelligent, dependable, and economical decision to drive it.

Understanding Factory Automation: More Than Just Robots

When the majority of the population thinks of factory automation, they imagine huge six-axis robotic arms welding car bodies in a shower of sparks. Although this is definitely an aspect of automation androbotics, it is just a fragment of a much bigger, more complex puzzle.

In its simplest form, factory automation involves the use of technologies—specifically integrated systems, such as control systems, computers, machinery, and information technology—to perform tasks and processes in a manufacturing facility automatically with minimal human intervention.

The main objective is not merely to substitute individuals or replace human operators, but to supplement and streamline the whole production chain. It is about developing a system in which machines, software and people collaborate to produce productivity, quality and safety levels that cannot be attained by manual labor alone. The goal is to optimize operations, often requiring only minimal human inputfor supervision.

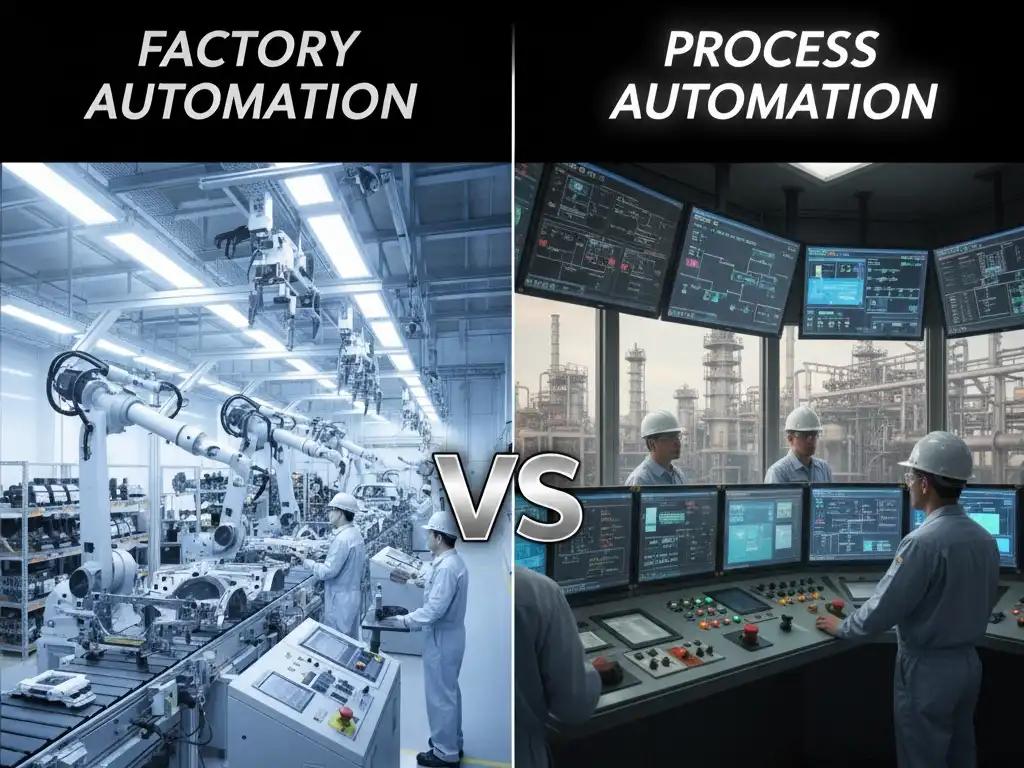

One of the most important distinctions that should be explained here is Factory Automation vs. Process Automation.

| Feature | Factory Automation | Process Automation |

| Main Focus | Production of discrete objects (countable items) | Continuous stream of materials |

| Examples | Smartphone assembly, bottling drinks, metal stamping, car manufacturing | Oil refinery, chemical plant, wastewater treatment plant |

| Objective | Assembling and manufacturing individual items | Monitoring and regulating variables like temperature, pressure, flow rate, and chemical composition |

| Operation | A sequence of manual actions like grip, move, place, weld, fasten, inspect | Continuous material flow, controlling various variables |

| Control Method | Mechanical and automated tools for precise operations | Automated systems control temperature, flow, pressure, etc. |

| System Nature | Discrete system, involving countable objects | Continuous system, with material flowing through processes |

| Automation Focus | Various individual actions and precise assembly | Measurement, adjustment, and optimization of material flow |

Although both of them share similar core automation technologies (such as controllers and sensors), their applications are quite different. Automationin factories concerns the actual production and assembly of goods, and it is here that the selection of physical actuators, or muscles, is of the greatest importance.

The Core Benefits: Why Automate Your Factory?

Automationis not a technological decision; it is a business decision. The rationale lies in a clear, compelling return on investment (ROI)that affects all aspects of the operation. The benefits of factory automation are a potent combination of tangible gains.

Gaining Unmatched Productivity and Quality

This is the most glorified advantage, and with reason. Even a human worker, however skilled and committed, is limited by human capabilities. They need breaks, work in shifts, and are prone to fatigue and distraction, which may cause errors or inefficiencies.

An automated system runs on another clock.

- 24/7/365 Operation: Automated lines can operate 24/7, only interrupted by scheduled maintenance. This essentially alters your production capacity, enabling you to satisfy demand spikes without corresponding rise in labor expenses.

- Speed and Throughput: Machines execute their designated tasks at a steady, optimal speed, each and every time. A pneumatic press can stamp a part in a fraction of a second, and can repeat the same operation 10,000 times with the same speed and force. This high throughput is a primary goal.

- Relentless Consistency (Quality): This is, perhaps, the best advantage of automation. One time a human hand may tighten a bolt to 9.8 Nm and the next time to 10.1 Nm. It is tightened to 10.0 Nm, with a negligible tolerance, each time by an automated driver. It is this unremitting uniformity, or consistency, that forms the basis of contemporary quality control. It achieves a level ofprecision that manual labor cannot sustain, which drastically improves overall production efficiency. It eliminates human error, which is the major cause of defects. The outcome is a drastic decrease in scrap, rework, and customer recalls, which will cement your brand as a reliable one.

Enhancing Worker Safety While Reducing Costs

The factory floor is a hazardous place and there are numerous hazardous environments. Automation is a direct reaction to this because it acts as a shield to your employees.

- Improved Safety: Automation is most effective in the so-called 3D jobs: Dirty, Dull, and Dangerous. Moving heavy components, handling toxic materials, handling molten metal, or mind-bending, repetitive work that leads to ergonomic injuries (including carpal tunnel syndrome) can be handed over to machines. This not only reduces the liability and insurance of a company, but it actually improves the quality of work. It liberates your human workers of hazardous work and they can be re-trained to more productive work like quality control, system maintenance and programming.

- Reduced Operating costs: The long-term financial prospects are good.

Sure! Here’s the same information presented in English, in a clean table format:

| Category | Description |

| Labor Optimization | You get much more out of each employee and can grow your business without adding employees in a linear manner. |

| Material Savings | Automation is highly accurate, meaning less waste. Materials are cut, stuffed, and assembled correctly the first time. |

| Energy Efficiency | Modern automated systems, particularly pneumatic systems, can be designed to be very efficient, consuming resources only when an action is performed. This focus on lower energy use also contributes to corporate sustainability goals. |

The Key Components: What Makes an Automated System Work?

You must know the parts to appreciate the whole. An automated system resembles a living organism, with the brain, senses, muscles, and nerves of the system being the components.

– The Brain (PLC): The Programmable Logic Controller (PLCs) is the industrialized computer that serves as the brain of the majority of automated lines. It’s the decision-maker. It continuously reads sensor data and executes a program that is pre-written to send out “output” commands to the actuators. These form the core of most industrial control applications.

– The Senses (Sensors): These are the eyes, ears and touch of the system. The PLC is fed with information through sensors and can understand the state of the world. They may be proximity sensors (to check the presence of a part), vision systems (to check defects), and pressure sensors. Smart sensors are increasingly employed in improved data collection.

– The Muscles (Actuators): This is the place where the physical work is performed. When the PLC chooses to do something, it commands an actuator to move. These are the things that catch, push, pull, twist, lift and press. Three major types exist:

| System Type | Description |

| Pneumatic Systems | Motion is produced by compressed air (e.g., in cylinders, grippers, and valves). |

| Hydraulic Systems | Motion is produced by means of pressurized fluid (typically oil), usually for very high-force applications. |

| Electric Systems | Electric motors (servos or steppers) are used to provide extremely fine, programmable motion. |

– The Skeleton (Robotics): This is the physical structure that houses and moves the actuators and tools. It can be as simple as a two-position linear slide or as complex as a 6-axis articulated robotic arm.

– The Nerves (HMI, SCADA & Software): This is the interface and communication layer.

– HMI (Human-Machine Interface): The touchscreen or panel that allows a human operator to monitor the system, set parameters, and troubleshoot alarms.

– SCADA (Supervisory Control and Data Acquisition): A more sophisticated software that provides a control room view of the entire factory, gathering information on multiple PLCs to monitor the overall production and performance.

The Four Levels of Automation: From Simple Tasks to Smart Factories

Automation is not a black and white switch. It is a process, which is sometimes referred to as a ladder having specific rungs. Knowing these levels of automation will assist you in determining where your facility is at the moment and what the next logical step could be based on your required level of operator involvement.

| Level | Name | Description | Example | Key Characteristics |

| Level 1 | Fixed (or Hard) Automation | This is used for very repetitive tasks at high speed with no flexibility. It is effective for mass production of a single product but difficult and costly to reconfigure. | Bottling line, mechanical stamping press | High-speed, repetitive tasks; lacks flexibility; expensive to re-tool for new products. |

| Level 2 | Programmable Automation | Allows modifications to operations by changing the program. Can process a batch of one product, then switch to another. Changeovers may cause some downtime. | CNC machine | Reconfigurable through programming; batch processing; downtime during changeover. |

| Level 3 | Flexible (or Soft) Automation | Can handle a variety of tasks with minimal downtime between changeovers. It adapts to different products on the same line. | Automotive assembly line (different models, options) | Highly flexible; minimal downtime; adapts to varying tasks and products; reduces human involvement. |

| Level 4 | Integrated Automation (Industry 4.0) | Full integration into the entire business process. The system is connected via IoT, uses AI and machine learning for real-time optimization, predictive maintenance, etc. | Smart factory, Industry 4.0 system | Fully integrated with business processes; real-time optimization; predictive maintenance; AI and IoT enabled. |

Real-World Automation: Examples Across Industries

The principles of factory automation solutions are universal, and their implementation is specific to the needs of a particular manufacturing process.

- Automotive: This is the most apparent one, especially in large automotive plants. Robotic arms are able to do their work with absolute accuracy, whether it is spot welding a car frame or putting on a perfect coat of paint in a closed, vapor-filled chamber (a job too dangerous to be done by humans). This is a classic example of automotive manufacturing leveraging assembly lines.

- Electronics: This is an industry that is dependent on high speed and microscopic accuracy. “Pick-and-place” machines are machines that use pneumatic grippers and vacuum suction to place thousands of small parts onto circuit boards in an hour- a task that cannot be reliably done by a human hand.

- Food & Beverage: Speed, hygiene, and reliability are the most important. Pneumatic systems are the best option in this case. They drive the machines that fill bottles, seal packages (packaging), sort products by shape or weight, and pack cases onto pallets, all in a washdown-safe environment on a high-speed production line. This is common in the beverage industry.

Pharmaceuticals: This industry requires total accuracy and sterility. The automated systems fill the vials with the precise dosage of medicine 100 percent of the time. The vision systems are high-speed and check each pill, discarding those with the slightest defect, which guarantees compliance and patient safety.

Why Pneumatic Parts are a Smart Choice for Your Automation

We have observed the automated system. We have examined the brain (PLC), the senses (sensors) and the skeleton (robotics). Now we have to consider the “muscles”–the actuators that do the actual work.

Although electric servos (commonly found in cobots in complex, collaborative tasks) are highly precise and hydraulic systems are incredibly powerful, in a large number of factory automation tasks, pneumatic componentsare the better, smarter, and more strategic option. They are factory horses. Being a professional manufacturer, we have observed the firsthand experience of how the correct pneumatic componentscan make the difference between the success of a system.

The Advantage: Unbeatable Cost-Effectiveness and Durability

Cost and reliability are not features when you are designing a system to execute millions of cycles, but rather the whole basis.

- – Reduced Acquisition Cost: Pound per pound of force, a pneumatic cylinder is much cheaper to buy than a similar electric servo motor and drive. This enables you to use more automation within your budget, which is highly scalable.

- – Simplicity and Durability: That is the key. A pneumatic cylinder is a simple model: a piston, a closed tube, and a rod. No complicated circuit boards to overheat, no fragile encoders to adjust. This is a very basic design that makes them very durable. They are resistant to shock, vibration, dusty, dirty or wet conditions that would ruin an electric motor.

- – Low Maintenance: When a pneumatic part finally fails after millions of cycles, it is usually a simple, cheap replacement of a seal that can be accomplished in a few minutes, not an expensive, complicated electronic repair. We design our parts as professional manufacturers to do just this. We understand that reliability is the most important thing, and our products are created to work under the conditions of the real world of the factory floor, where failure is not an option, and inefficiencies should be removed.

The Value: Built for Speed, Power, and Safety

The worth of pneumatics is much more than its cost. It is based on its natural physical characteristics that provide a distinct set of performance advantages.

- – Speed and Power: Pneumatic systems are quick. They are ideal in bang-bang or end-to-end motion: clamping a part, ejecting a finished product, or stamping a logo. They provide high cycle speeds and acceleration. Moreover, their power-to-weight ratio is outstanding. Hundreds or even thousands of pounds of linear force can be produced by a small, lightweight pneumatic cylinder, and it is incredibly powerful in a small footprint.

- – Intrinsic Safety: This is the advantage that cannot be compromised. Compressed air is used in pneumatic systems. The point of action has no electricity, and therefore no sparks. This renders them the sole secure and sensible option in unstable or risky conditions. Pneumatics is not only a good idea when you are automating a paint spray booth (flammable fumes), a chemical processing line, or a grain mill (combustible dust), but a vital safety consideration.

- – Cleanliness: Pneumatic systems operate on clean filtered air unlike hydraulic systems which may leak messy oil. This renders them suitable in hygiene sensitive sectors such as food and beverage, pharmaceuticals and electronic manufacturing.

Our pneumatic cylinders and valves are designed with high precision to ensure your line runs at full speed with maximum uptime. Beyond this, they offer exceptional durability, backed by robust certifications and features that allow you to automate with confidence, even in the most demanding environments. With IP65, IP67, and IP68 ratings, our cylinders provide superior protection against dust and water, ensuring reliable performance in harsh conditions. Additionally, our pneumatic cylinders from China are built to last, offering a lifespan ranging from 3 million to 10 million cycles, guaranteeing long-term, dependable performance in even the most rigorous applications.

Build Your Automated Future with the Right Partner

Factory automationis not a luxury of the few anymore, it is a strategic necessity of every manufacturer. It is the time-tested way to the next stage of productivity, the quality of the products, and the safety of your employees, and optimizing your entire business processes.

As you have observed, an automation system is a complicated combination of brains, senses, and muscles. The decisions you make regarding every component will determine the performance and visibility of your whole operation. Modern systems, using standards like OPC to communicate, can even feed data directly to operators via tablets on the floor.

Once you come to the point of selecting the “muscles” of your system, the actuators that will do the heavy lifting, the high-speed work, and the critical work, you require a solution that is robust, reliable, and cost-effective. The solution, and still is, pneumatic parts, to a colossal variety of applications.

Conclusion

It is essential to select the appropriate components, yet it is equally important to collaborate with a seasoned pneumatic parts specialistwho understands industry best practices. You require a partner that is knowledgeable of the requirements of your industry and capable of providing solutions that are sustainable.

If you are looking for factory automation systems that balance exceptional cost-effectiveness with iron-clad reliability, our expert team is ready to help. Contact us today to discuss your application and discover how our high-quality pneumatic parts can power your automated future.